Learn more about Pozzotive and how it can make your next project better

and more sustainable.

How are Pozzotive products made?

Pozzotive products are manufactured from waste bottle glass that would otherwise be landfilled. The majority of glass is sourced from material recovery facilities (MRFs) that sort curbside-collected recyclables into homogeneous product streams, one of which is glass. Like all recovered recyclables, the glass is unclean and must be cleansed to a very high standard. Pozzotive utilizes an innovative patented process to separate glass from non-glass materials, clean the residual organics from the glass containers and mill the glass into a fine powder. The most common application for the end product is use as a high performance ground glass pozzolan in the production of concrete.

How does a pozzolan make concrete stronger

and more durable?

A pozzolan is an important component of high-performance concrete because of the unique chemical reaction that takes place in the concrete mix. When cement is hydrated in a concrete mix, the resulting chemical reaction produces a number of compounds, the most important of which is the cement paste that binds the aggregates into a hard matrix. Cement paste is referred to as calcium silicate hydrate, or C-S-H. Another cement hydration product is calcium hydroxide, or C(OH)2, which causes porosity and weakness in the concrete matrix. Pozzolans chemically react to convert bad CH into good C-S-H, known as a pozzolanic reaction, making them an essential component of high-performance concrete.

What makes Pozzotive a better ground glass

pozzolan?

The most commonly used pozzolan in the manufacture of concrete is fly ash derived from coal-burning power plants, a declining industry that has precipitously reduced the availability, quality and cleanliness of fly ash. Pozzotive GGP is a safer, cleaner alternative that not only has significant environmental benefits, but acts to make concrete stronger and longer lasting.

Not all ground glass pozzolans are equal. Two key attributes set Pozzotive apart from a performance perspective: optimal and reliable particle size and a clean and consistent chemical composition. First, particle size plays a huge role in the pozzolanic reaction that imparts strength and durability to high performance concrete. Years of testing and use have refined the manufacturing process for Pozzotive to tightly control the range of particle size to maximize the efficiency of its pozzolanic reaction.

Second, the chemical composition of bottle glass is the same worldwide, however post consumer glass is dirty and must be cleaned to a very high standard before processing, potentially creating wide differences between ground glass pozzolans just based upon different cleaning processes. Pozzotive is cleaned, sorted and milled using a precise, patented process which yields a highly consistent, reliable and reproducible pozzolan. Additionally, Pozzotive is free of hazardous components and, unlike fly ash, contains no carbon which adsorbs air entraining admixtures.

How is Pozzotive used in concrete?

Pozzotive is a safer, cleaner and better performing pozzolan that, depending on the mix design, can replace up to 50% of portland cement in concrete. By substituting up to 50% of cement with Pozzotive, not only are CO2 emissions reduced on an almost ton-for-ton basis, but the resulting concrete is made more durable, longer lasting and more impervious to the impact of chloride, sulfate attack and the stresses of the freeze/thaw cycle.

How does Pozzotive make concrete

more sustainable?

Concrete is one of the most versatile and abundant materials used in the construction industry worldwide. Because Pozzotive reduces the amount of portland cement required to make concrete, it eliminates the harmful CO2 produced by portland cement on an almost ton-for-basis.

Additional environmental benefits of Pozzotive are:

- A dramatic 95% reduction in the carbon footprint of cement results in significant reduction in the carbon footprint of concrete and significant reduction in hazardous air pollutant emissions emitted to the atmosphere from cement production.

- Pozzotive produces a higher performing, more durable concrete that has a longer life span, thereby saving time, energy, materials, maintenance, and replacement costs over the life of the project.

- A brighter/whiter pozzolan creates a lighter concrete that reduces the “heat island” effect in urban areas.

- Pozzotive raw material is sourced regionally, manufactured regionally and utilized regionally, a perfect example of the circular economy that also minimizes transportation requirements.

- Pozzotive is a regionally made product created from post-consumer glass, both attributes contributing to LEEDTM accreditation.

- Harvesting 100% of post-consumer glass, even that which is deemed unusable, keeps glass out of our rapidly diminishing landfills

- Using sustainable, readily available waste glass dramatically reduces the mining of non-renewable natural resources used to manufacture cement.

What are the benefits of Pozzotive in

fresh concrete?

Unlike other pozzolans, Pozzotive does not retard set time which makes Pozzotive suitable for cold weather jobs and products where forms must be stripped daily such as prestress and precast concrete and cast stone. Pozzotive increases concrete workability and the ability to retain air that is required for concrete exposed to the elements. Unlike all other pozzolans, glass does not absorb moisture which results in reduced water requirement. This attribute increases concrete strength while maintaining the increased pumpability and workability.

What are the benefits of Pozzotive in

hardened concrete?

Pozzotive not only makes concrete sustainable and easy to work with, it creates a higher performing, longer lasting concrete with the following attributes:

- Improved adhesion of the aggregates to the cement paste, creating a stronger concrete

- Extreme resistance to chloride penetration that results from the application of road salts to melt ice and snow

- Resistance to sulfate attack, a problem in coastal areas and waters containing sulfur compounds

- Reduced moisture penetration which significantly suppresses the negative effects of freeze-thaw cycles

- Concrete with 40% Pozzotive is expected to last five times longer, offering major savings in long-term infrastructure costs

- Prevention of efflorescence, which is an undesirable whitish, powdery deposit on the surface of concrete

What is the difference between amorphous silica

and crystalline silica?

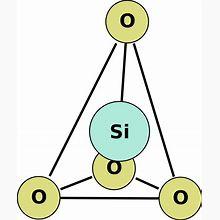

One property common to all pozzolans is the presence of amorphous silica. Quartz sand is made up of crystalline silica. The silica in both glass and sand are in the form of silicon tetrahedrons having a silica atom in the center and four oxygen atoms at the apices of the tetrahedron. In crystalline silica, the tetrahedrons are lined up in rows that are stacked side-by-side and on top and bottom in a neat and organized manner. The bonds between the tetrahedrons are strong because of this orderly structure. Glass is made by melting crystalline silica along with other ingredients and cooling it rapidly. In the liquid form, the silica tetrahedra are randomly located with respect to each other and if cooled fast, the tetrahedrons essentially freeze in place in an amorphous, or random, structure. The bonds between the tetrahedra in this random state are much weaker than when in the organized crystalline state. These weaker bonds allow for the pozzolanic reaction to occur with amorphous silica and not with crystalline silica.

One property common to all pozzolans is the presence of amorphous silica. Quartz sand is made up of crystalline silica. The silica in both glass and sand are in the form of silicon tetrahedrons having a silica atom in the center and four oxygen atoms at the apices of the tetrahedron. In crystalline silica, the tetrahedrons are lined up in rows that are stacked side-by-side and on top and bottom in a neat and organized manner. The bonds between the tetrahedrons are strong because of this orderly structure. Glass is made by melting crystalline silica along with other ingredients and cooling it rapidly. In the liquid form, the silica tetrahedra are randomly located with respect to each other and if cooled fast, the tetrahedrons essentially freeze in place in an amorphous, or random, structure. The bonds between the tetrahedra in this random state are much weaker than when in the organized crystalline state. These weaker bonds allow for the pozzolanic reaction to occur with amorphous silica and not with crystalline silica.

How long has Pozzotive been in use?

Pozzotive has been in use for over 10 years as a concrete pozzolan in applications ranging from the United Nations Plaza pavers, to sidewalks in New York City and at Google Headquarters in California. Pozzotive was used in the first high-rise pour nationally by the Durst Organization, in the Second Avenue Subway and in marquee buildings and projects throughout the New York area. Learn More..

How else can I use Pozzotive?

While Pozzotive pozzolan is primarily being marketed for use as a pozzolan in the manufacture of concrete, Pozzotive-branded products can be used as safe and high performing industrial fillers and as blasting abrasives. Click here to learn more…

How can I specify Pozzotive in my next project?

Contact us to learn how to make your next project more sustainable with Pozzotive.